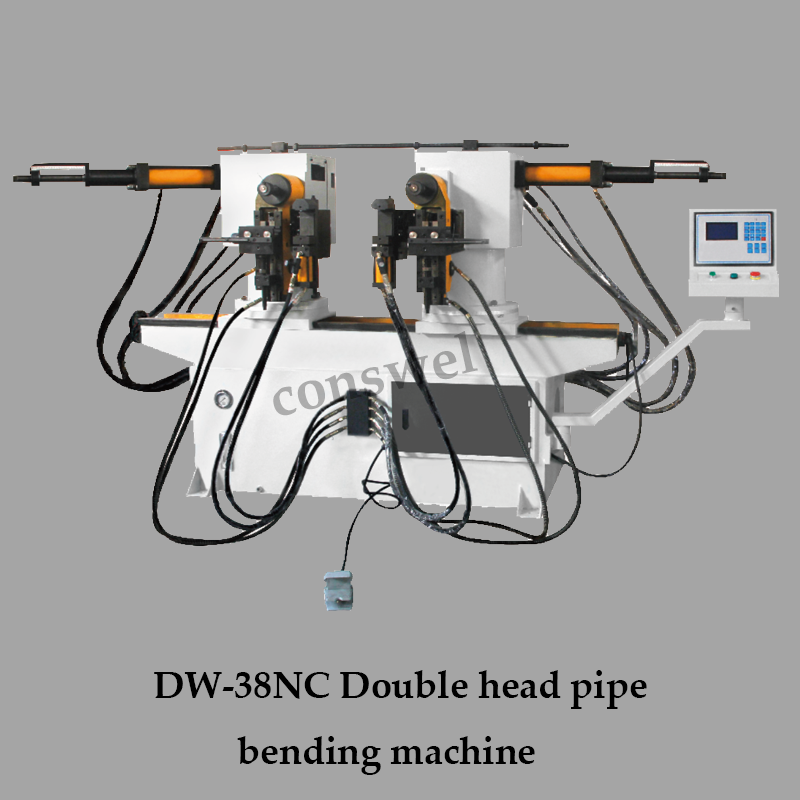

The double-head pipe bending machine is a mechanical equipment that can efficiently bend pipes. The following is an introduction from multiple aspects:

Equipment structure and principle

Structure:

There are two independent bending work heads, equipped with feeding mechanism, clamping device, bending mold and other components. The feeding mechanism can accurately convey the pipe, the clamping device can firmly fix the pipe, and the bending mold determines the bending shape of the pipe.

Principle:

With the help of hydraulic or servo motor drive, when the pipe is sent to the specified position and clamped, the two bending work heads perform bending operations on both ends of the pipe at the same time or separately according to the preset program and parameters.

Performance characteristics

Efficient production:

It can process both ends of the pipe at one time, which greatly improves the production efficiency compared with the single-head pipe bending machine and is suitable for mass production.

High precision:

The bending angle, radius and other parameters are accurately controlled by the CNC system to ensure the bending accuracy and meet the high-precision requirements of pipe bending in different industries.

Strong flexibility:

By replacing the mold, it can adapt to a variety of materials (such as stainless steel, carbon steel, aluminum alloy, etc.) and specifications of pipes, and can complete bending of different shapes, such as U-shaped, S-shaped, etc.

Easy to operate:

Most are equipped with an intuitive human-machine interface. Operators only need to enter relevant parameters or call the program to easily complete the operation.

| Specification \ Model | 38 | 42 |

| Motor Power | 5.5 | 5.5 |

| Oil Pressure Capacity | 120 | 120 |

| Oil Pump Displacement | 17 | 22 |

| Maximum System Pressure | 14 | 14 |

| Maximum Pipe – bending Capacity | Φ38×2 | Φ42×2 |

| Applicable Bending Radius | 38 – 200 | 42 – 250 |

| Range of Double Bending Centers | 170 – 1450 | 170 – 1450 |

| Maximum Bending Angle | 185° | 185° |

| Bending Speed | 50°/s | 50°/s |

| Number of Pipes Bent at One Time | Φ13×3 | Φ15×3 |

| Saw Blade Size | Φ19×2 | Φ25×2 |

| Machine Weight | 2200Kg | 2700Kg |

| Machine Volume | 2700×900×1350 | 2700×900×1800 |